How important to present a perfect prototype in trade show?

Metalstar Prototype produced some charcoal grill (BBQ) prototypes to one of our customers in the second half year of 2017. These prototype grills were put on several trade shows in USA and Europe in the past few months, and the customer company received very positive business reactions for this product, so the company owner – Mr. Li just shared with us his happiness, and thank to us for our excellent prototyping works.

Those grill prototypes above mentioned are big 22inch charcoal grills. It is designed with deep drawn double wall case (about 300mm in depth), deep drawn round lid, deep drawn ash can and special shape sheet metal formed legs. The sheet metal formed legs were required with textured powder coating, and all deep drawn parts were required with high glossy black enamel coating. For business reason, it is not proper to put pictures of the new grill here, so we just make a summary about how important to present a perfect prototype in trade shows and how to make high quality deep drawn prototype, let me use this charcoal grill prototype as an example,

1, as the grill prototype above mentioned, because the main components are the deep drawn cases, lid and ash can. So, perfect deep drawn prototypes are the key to a trade showing success. In the past, many BBQ companies use aluminum or steel CNC machining way to make these deep draw prototype parts, but usually it costs very high and cannot get designed thickness or weight or correct surface finishing in this way, and more important is that this way oftens cannot give good feeling to customers. So, to make the customers impressed in the trade show, the products are presented with correct raw materials and correct surface finishing is very important to many BBQ compaines.

2, usually, to make this kind of big and deep drawn prototype parts, especially for big deep drawn prototype parts, the prototyping works require rich experienced designer for designing prototype mold(tools), large CNC machinery and large hydraulic deep draw machine. So, the prototype factory who has rich experienced staffs and equips with sufficient machinery is an important factor for final delivering qualified prototypes on schedule.

3, for deep drawn prototype parts, the raw material selection is another key factor. If you want to present high quality enamel coated prototypes to customers, then you must use specific raw material of sheet steel, because only correct or specific raw material can ensure the final high-grade enamel coated parts. With experience accumulations for more than 14 years, Metalstar prototype understands and being an expert for material selection for prototypes. So, every time, when our customer has a prototyping demand, we must check with our customer for his expectation, so that we can well arrange and manage the whole process of raw material purchasing and usage.

4, it is very difficult to make big and deep drawn parts using prototype tools, for most of the prototype factories, one of the big challenge for them is that how to eliminate the deep draw marks which is usually restricted by prototype tools’ design and tools’ raw material selection. At Metalstar prototype, we successfully resolved this issue years ago, which was by applying specific tools design technology, and applying with specific refining process after deep drawing process.

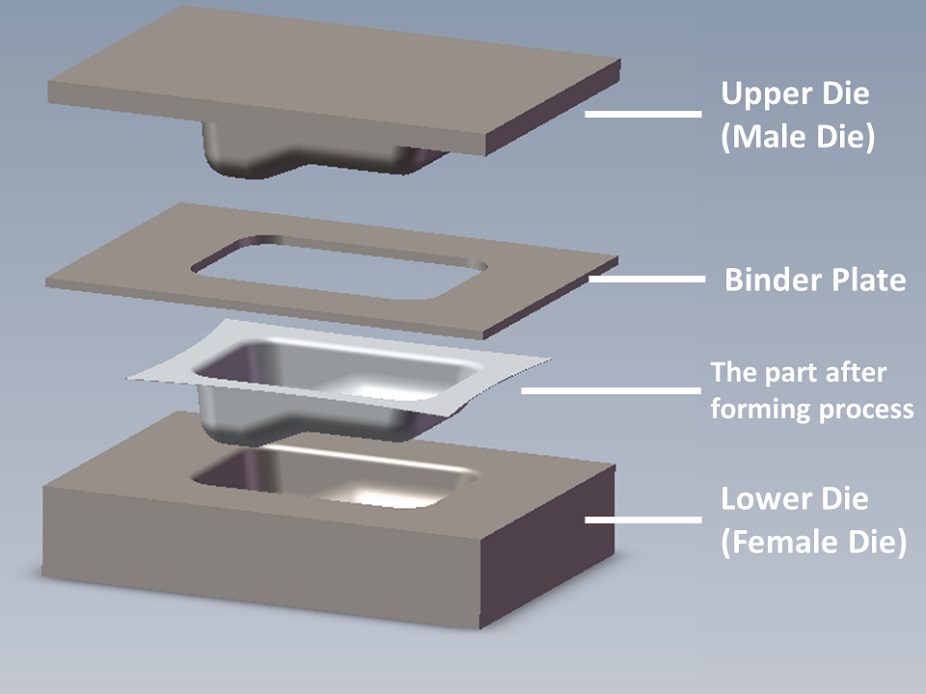

So, with sufficient equipments invested and more than 14 years prototyping experience accumulations, these advantages ensure Metalstar prototype to deliver high quality prototype with short lead time, especially for big and deep drawn prototypes. The following illustration for your reference about our deep draw stamping way for prototype parts.

At the end, welcome to view our website at www.gzmetalstar.com for more information and welcome to visit our factory when you get time someday.

Thanks for reading!

Best wishes!